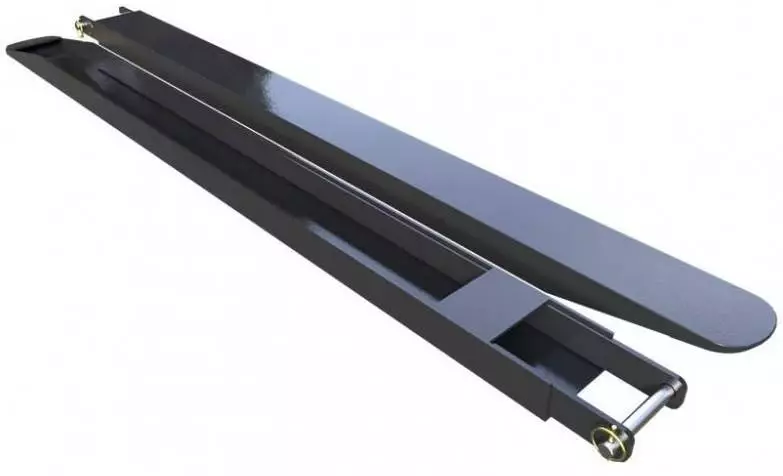

Fork Extensions: Things to Consider!

Fork extensions are invaluable tools for handling oversized or awkward loads with your forklift. However, to ensure safety and compliance, several factors must be considered before integrating them into your operations.

1. Compatibility with Your Forklift Forks

It's crucial to ensure that the fork extensions are the correct size to fit over your existing forklift forks. Extensions that are too narrow won't fit properly, while those that are too wide may rattle or come loose during operation. To determine the right fit:

- Measure the width of your forklift forks.

- Measure the thickness at the heel of the forks.

- Compare these measurements with the internal dimensions of the fork extensions.

For a range of heavy-duty fork extensions, visit our product page: Heavy Duty Fork Extensions.

2. Adherence to Legal Length Restrictions

According to safety regulations, the length of the fork extensions should not exceed 150% of the original fork length. For example, if your forks are 48 inches long, the maximum permissible extension length is 72 inches. Exceeding this limit can compromise the stability and safety of the forklift during operation.

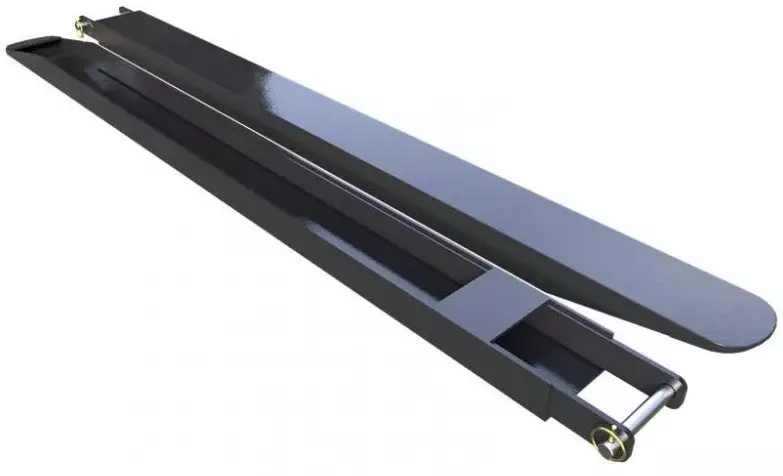

3. Presence of Removable Heel Pins

Fork extensions equipped with removable heel pins allow for easier installation. By laying the extensions on the floor, you can drive the forklift forks into them without manual lifting, enhancing safety and efficiency during attachment.

4. Certification and Compliance

It's imperative that all forklift extensions are certified, ensuring they meet industry standards and safety regulations. Certified extensions come with documentation upon delivery, providing assurance of their compliance and quality.

5. Safety and Operational Considerations

When using fork extensions, keep the following safety tips in mind:

- Load Capacity: Be aware that extensions can alter the forklift's load capacity. Always refer to the manufacturer's guidelines and ensure that the combined weight of the load and extensions doesn't exceed the forklift's rated capacity.

- Load Center: Extensions shift the load center forward, which can affect stability. Ensure that the load center remains within safe limits to prevent tipping.

- Operator Training: Operators should be trained on the specific handling characteristics of forklifts equipped with extensions.

- Regular Inspections: Before each use, inspect the extensions for signs of wear, damage, or structural defects.

Conclusion

Fork extensions can significantly enhance the versatility of your forklift, allowing for the safe handling of larger loads. By considering compatibility, legal restrictions, safety features, and certification, you can ensure efficient and compliant operations.

For expert advice or to discuss your specific requirements, feel free to contact us:

- Email: info@liftruck.co.uk

- Phone: 0800 458 8025