Need to Be Certified?

Operating a forklift in the UK requires proper certification to ensure safety and compliance with legal standards. Whether you're an employer seeking to certify your staff or an individual aiming to enhance your qualifications, understanding the certification process is crucial.

Why Certification Matters

Certification demonstrates that an operator has received adequate training to handle forklifts safely. It helps prevent workplace accidents, ensures compliance with the Health and Safety Executive (HSE) regulations, and can improve employment prospects.

How to Obtain Forklift Certification

To become a certified forklift operator in the UK, follow these steps:

- Choose an Accredited Training Provider: Enroll in a course offered by a provider accredited by bodies such as RTITB, ITSSAR, NPORS, or AITT.

- Complete the Training: Undergo theoretical and practical training covering forklift operation, safety procedures, and equipment maintenance.

- Pass the Assessment: Successfully complete both written and practical evaluations to demonstrate your competence.

- Receive Certification: Upon passing, you'll receive a certificate valid for a specified period, typically three to five years.

Maintaining Your Certification

Regular refresher courses are recommended to keep your skills up to date and maintain compliance with evolving safety standards. Employers should also ensure that their operators' certifications are current.

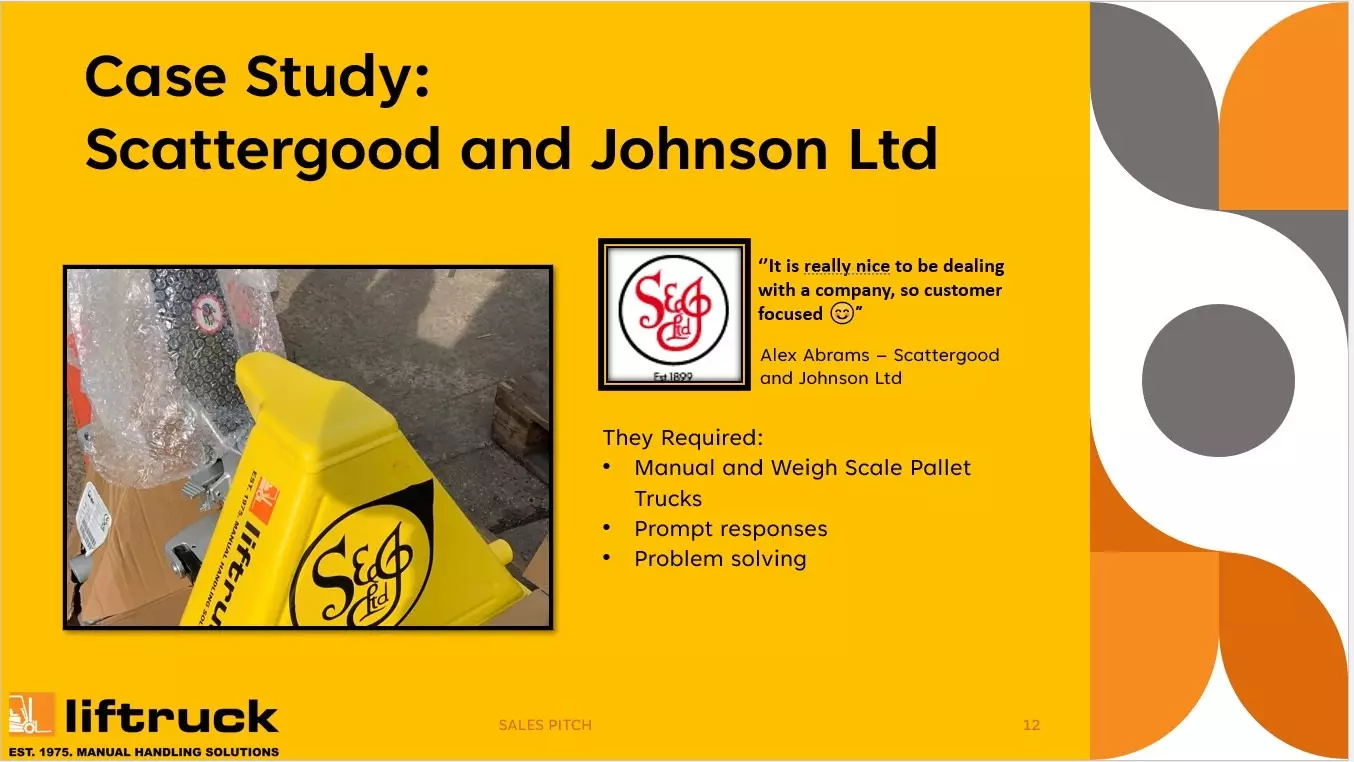

Enhance Your Operations with the Right Equipment

Certified operators can maximise efficiency and safety by using appropriate equipment. Explore our range of products designed to complement your operations:

Contact Us

For more information on certification or to find the right equipment for your needs, please get in touch:

- Email: info@liftruck.co.uk

- Phone: 0800 458 8025